Rolling Stock Metalwork

As the UK's largest laser cutting and fabrication company, we have dedicated aluminium welding clean zones focussed solely on rolling stock metalwork and we also carry rail specific materials such as approved earth bonds and fasteners, working closely with world-class component manufacturers to ensure the highest level of quality.

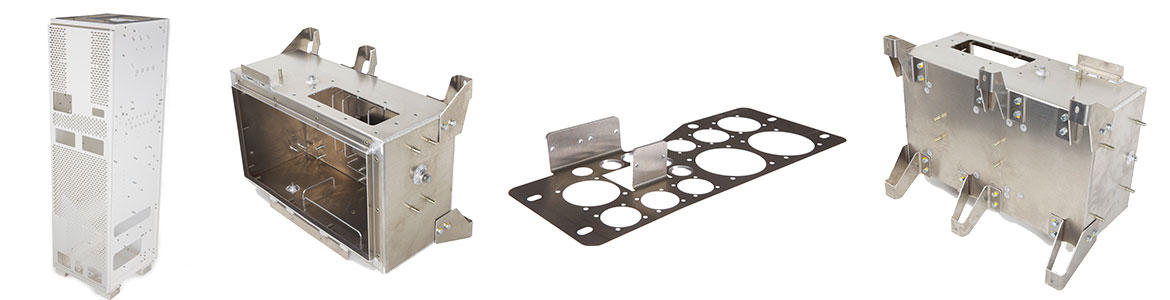

WEC Rail are an EN15085 accredited Rail specialist in the fabrication of complex aluminium metal work.WEC Rail also delivers high-quality rolling stock metalwork including structural metalwork, underframes, electrical enclosures and body end cubicles for large Rail OEMs and Prime contractors such as Bombardier Transportation and Hitachi Rail to name but a few.

From structural metalwork and under-frames through to electrical enclosures and body end cubicles, WEC Rail is experienced in delivering high quality rolling stock metalwork to the industry. We work closely with world-class component manufacturers to ensure the highest levels of quality and boast a comprehensive customer base featuring many well-known names in the rail industry.

On-board the train there are many electrical systems which require housing capable of withstanding extreme conditions. WEC Rail rolling stock cabinets are designed to withstand and resist harsh conditions such as shock, vibration and temperature, thus protect the electronics they house. WEC Rail offers bespoke cabinets especially for mobile environments; the cabinet dimensions can be altered to cater for unique location difficulties, enabling the available space to be used to full effect.